Time:2024-12-30

Time:2024-12-30

Source:青绿环境

Source:青绿环境

In the context of rapid urbanization and increasing pressure on resources and the environment, the innovation and application of waste sorting equipment production lines are of great significance.

A waste sorting equipment production line is an automated system that integrates a variety of technologies. Its working principle covers primary crushing, magnetic separation, air separation, flotation, and optical-electrical sorting. Primary crushing reduces the volume of large construction waste; magnetic separation recovers metal resources; air separation separates light and heavy materials; flotation distinguishes materials by density; optical-electrical sorting relies on optical sensors and image recognition technology for fine sorting.

This production line has many technical features. First, it has a high degree of automation, with computers controlling the entire sorting process, reducing manual operation, and improving efficiency and accuracy. Second, it has high sorting precision, with a combination of sorting technologies achieving efficient recovery of valuable materials. Third, it is environmentally friendly and energy-saving, reducing dependence on landfills and incinerators, and decreasing carbon emissions. Fourth, it has strong adaptability, allowing for adjustment of sorting strategies according to different construction waste.

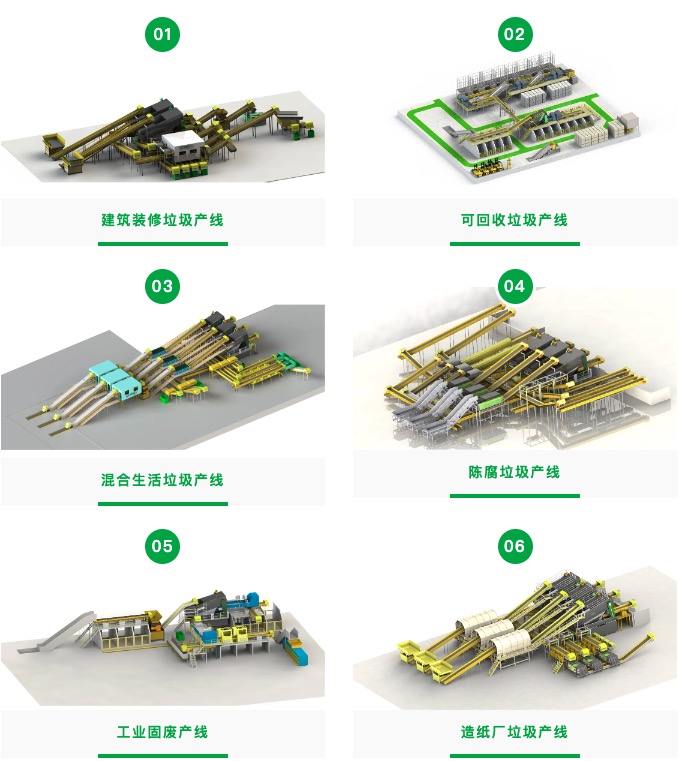

In practical applications, waste sorting equipment production lines have been widely used in various scenarios. They play an important role in construction sites, demolition sites, waste building material recycling stations, and urban waste treatment centers. For example, a city that has introduced an automatic waste sorting production line with an annual processing capacity of 100,000 tons has improved the efficiency of waste sorting, laying the foundation for subsequent resource utilization and harmless treatment.

The integration of intelligent and automated technologies has brought new development to waste sorting equipment production lines. Intelligent technology, with the help of sensors, image recognition, and machine learning, achieves automatic identification and classification of waste. Automated technology constructs an efficient production line through robotic arms, conveyor belts, and sorting systems. The combination of the two allows the equipment to learn and optimize the sorting process on its own.

In the future, with technological advancements and increased environmental awareness, waste sorting equipment production lines will become more intelligent and refined, handling more complex waste with lower energy consumption and easier and safer operation. Moreover, the sorted building materials will be used more in new construction projects, creating a resource recycling system. This will not only solve waste disposal problems but also promote resource recycling and environmental protection.

Prev

Prev