Time:2025-01-15

Time:2025-01-15

Source:青绿环境

Source:青绿环境

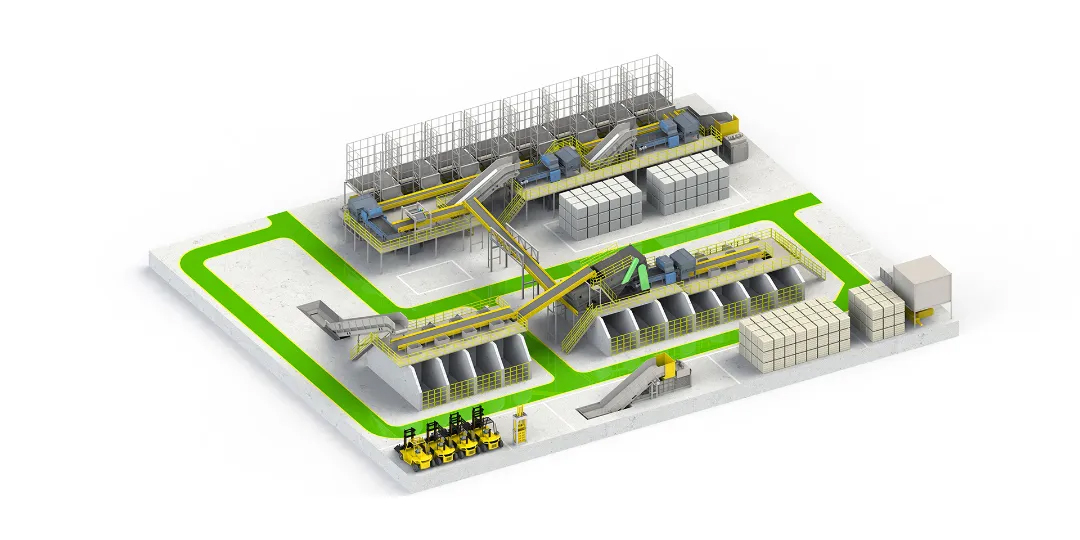

Recyclable Material Sorting Equipment is specifically designed to efficiently separate and classify recyclable materials such as plastics, metals, and paper from mixed waste. It utilizes advanced sensing technology, image recognition technology, and robotic arm gripping technology to achieve automatic identification, classification, and sorting of waste, greatly improving the efficiency and accuracy of waste treatment.

Here are the specific applications of recyclable material sorting equipment in different fields:

Urban Domestic Waste Sorting Field

With the acceleration of urbanization, the volume of urban domestic waste has increased sharply. Recyclable material sorting equipment can efficiently classify a large amount of domestic waste, separating recyclables such as plastics, paper, and metals, achieving the recycling of resources and reducing the environmental impact of landfill and incineration, thereby improving the resource recovery rate and environmental quality of the city.

For example, in the waste treatment centers of some large cities, advanced optical recognition, magnetic separation, and air separation technologies are used to automatically sort domestic waste, processing thousands of tons of waste per day, significantly improving waste treatment efficiency.

Plastic Sorting Field

Waste plastics generated in the production and consumption of plastic products, as well as discarded plastic products in urban domestic waste, can be accurately sorted by material and color through recyclable material sorting equipment. For instance, using intelligent recognition systems and spectral analysis technology, it is possible to accurately distinguish different types of plastics such as PET, PP, and PE, as well as identify the color grades of plastics, providing high-quality raw materials for the regeneration of plastics, improving the purity and performance of recycled plastics, reducing production costs, and promoting the development of the plastic circular economy.

Some professional plastic recycling companies use high-precision plastic sorting equipment to finely classify the mixed recycled plastics, and then process them into various plastic products, such as plastic bottles and plastic pipes, achieving efficient resource utilization.

Recyclable Waste Sorting Field

In addition to plastics, recyclable material sorting equipment is also widely used in the sorting of various types of recyclable waste, including metals, glass, and paper. Through gravity separation, eddy current separation, and magnetic separation technologies, metals can be separated from other waste for smelting and reprocessing; using photoelectric sensors and density differences, glass can be separated from impurities, improving the quality and utilization rate of glass recycling; for paper, air separation and screening processes can be used to remove impurities and ink contamination, producing recycled paper products.

For example, in scrap metal recycling plants, sorting equipment can quickly and accurately select different types of metals such as iron, copper, and aluminum from scrap metal mixtures, improving the efficiency and economic benefits of metal recycling.

Waste Paper Sorting Field

In today's developed papermaking industry, the recycling of waste paper is crucial. Recyclable material sorting equipment can grade and screen waste paper, removing non-paper substances such as impurities, tape, and staples, as well as deinking the paper to improve the quality of recycled paper. At the same time, it can classify paper according to its type and quality, such as collecting newspapers, magazine paper, and packaging paper separately, for the production of different grades of recycled paper products, meeting the market demand for various types of paper.

Many large paper mills are equipped with advanced waste paper sorting equipment to ensure that the recycled paper produced has good physical properties and printability, reducing production costs and enhancing the market competitiveness of enterprises.

Electronic Waste Sorting Field

With the rapid pace of electronic product updates, the volume of electronic waste is also increasing quickly. Recyclable material sorting equipment can effectively sort recyclable materials such as metals, plastics, and glass from electronic waste. For example, through processes such as crushing, magnetic separation, and gravity separation, valuable metals such as gold, silver, and copper can be recovered from electronic circuit boards, and plastic casings and glass screens can also be separated for further resource utilization, reducing the environmental pollution of electronic waste and promoting the sustainable use of resources.

Professional electronic waste recycling companies use sorting equipment to extract valuable metals and materials from discarded computers, mobile phones, televisions, and other electronic products, reducing the dependence on primary mineral resources and minimizing the environmental hazards of electronic waste.

Prev

Prev