Time:2025-02-08

Time:2025-02-08

Source:青绿环境

Source:青绿环境

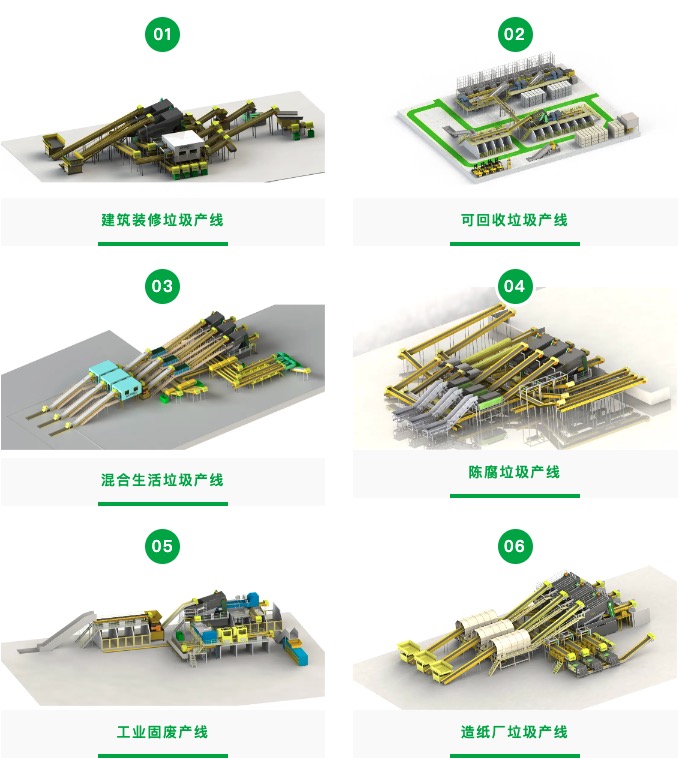

The garbage sorting production line has a high degree of automation, integrating various technologies such as conveying, screening, magnetic separation, and air separation. It can accurately separate recyclables such as metals, plastics, and paper, while also sorting out hazardous waste and kitchen waste. The efficient processing reduces labor costs and contributes to waste resource utilization and environmental protection.

I. Front-end Collection and Pre-treatment Equipment

- Garbage Collection Trucks

- These are used to transport dispersed waste to the processing plant. They are usually equipped with compression and sealing functions to minimize secondary pollution during transportation.

- Chain Plate Feeder

- Serving as the starting point of the production line, it evenly conveys mixed waste to the sorting section. It is characterized by wear resistance and high stability.

- Large Item Ejector

- Through gravitational action, it quickly separates large-volume waste (such as furniture and appliances) to prevent blockages in subsequent sorting equipment.

- Automatic Bag Rupturing Machine

- Used to shake out loose materials from garbage bags, facilitating subsequent crushing and sorting.

II. Core Sorting Equipment

- Drum Screen

- By rotating, it separates waste of different sizes. For example, it layers lightweight materials such as paper and plastic from heavy materials, making subsequent processing easier.

- Air Separation Machine

- Utilizing air power to separate lightweight waste (such as plastic bags and foam) from heavy waste, it improves sorting accuracy.

- Magnetic Separation Machine

- Specifically used for separating metal waste, such as recycling iron products.

- Manual Sorting Platform

- Equipped with belt conveyors, hoppers, and safety protection devices, it is used for fine sorting of complex or high-value waste (such as batteries and glass). It supports variable frequency speed adjustment to adapt to different working conditions.

- Fully Automatic Sorting Equipment

- Integrating image recognition, AI algorithms, and robotic arms, it can automatically classify waste such as plastics and metals, significantly improving efficiency and reducing manual intervention.

III. Subsequent Processing and Transportation Equipment

- Crusher

- Used to process large items of waste (such as tires and furniture). Common types include shearing and impact crushers. Crushing makes further sorting or recycling easier.

- Compactor and Baler

- These compress loose waste into blocks, reducing volume to lower transportation and storage costs.

- Conveyor System

- Including belt conveyors, screw conveyors, etc., they are responsible for material transfer between different sections. Some equipment can adjust speed according to process requirements.

IV. Intelligent and Environmental Auxiliary Equipment

- AI Sorting System

- At transfer stations or sorting centers, this system uses cameras and algorithms to identify types of waste, detect issues such as mixed loading and contamination, and optimize management processes.

- Odor Control and Fire Protection System

- Used for environmental control in sorting workshops, reducing odors and safety hazards.

- Dual-Network Integration Recycling Point

- Combining waste sorting with the recycling of secondary resources, it sets up a temporary storage warehouse for recyclables to promote resource recycling.

V. Configuration Suggestions

- Degree of Automation: Fully automatic sorting lines are suitable for high-throughput scenarios (such as urban waste treatment centers), while manual sorting platforms are more suitable for supplementary sorting of complex or high-value waste.

- Construction Waste Sorting: It is necessary to enhance the drum screen and large item ejector, and to match them with specialized crushing equipment.

- Environmental Compliance: Negative pressure air separation, sealed workshops, and wastewater treatment systems should be equipped to reduce the spread of dust and odors.

Prev

Prev