Time:2024-10-28

Time:2024-10-28

Source:青绿环境

Source:青绿环境

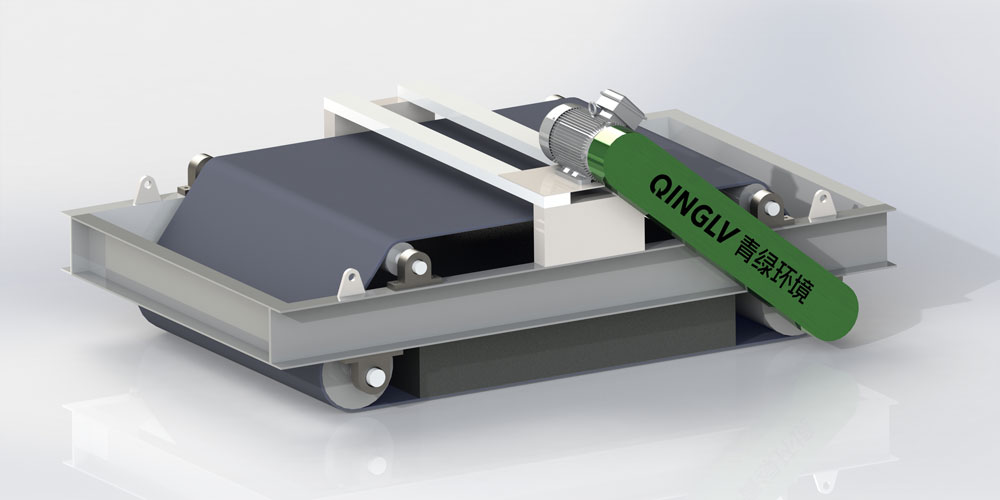

In the waste processing process, magnetic separators play a crucial role, especially in recycling metal waste. Selecting the right waste sorting magnetic separator can not only improve sorting efficiency but also reduce operational costs. So, how to choose the right waste sorting magnetic separator?

Firstly, consider the magnetic field strength of the separator. Different waste components require different magnetic field strengths for effective separation. Generally, a strong magnetic field is suitable for recycling scrap metals such as nails and rebar, while a weak magnetic field is suitable for separating non-ferrous metals like aluminum and copper.

Secondly, sorting accuracy is also an important consideration. A high-precision sorting magnetic separator can more accurately separate the target metals, reducing the instances of mispicking and missed picking, thereby improving the overall sorting quality.

Furthermore, the processing capacity of the equipment should not be overlooked. Choose a magnetic separator that can meet specific processing volumes according to actual production needs to ensure smooth operation of the production line. At the same time, the stability and durability of the equipment are also factors to consider, which relate to long-term operational costs and maintenance workload.

In addition, ease of operation and maintenance costs are aspects to consider when choosing a magnetic separator. Equipment that is easy to operate and maintain can greatly reduce the burden on staff and improve work efficiency.

Lastly, it is worth referring to market reputation and after-sales service. Choose a brand with high visibility and good reputation, and ensure it provides comprehensive after-sales service, so that timely technical support and solutions can be obtained when the equipment encounters problems.

In summary, choosing the right waste sorting magnetic separator requires a comprehensive consideration of multiple factors to ensure the purchase of the most suitable equipment for your own needs.

Prev

Prev