Time:2025-05-15

Time:2025-05-15

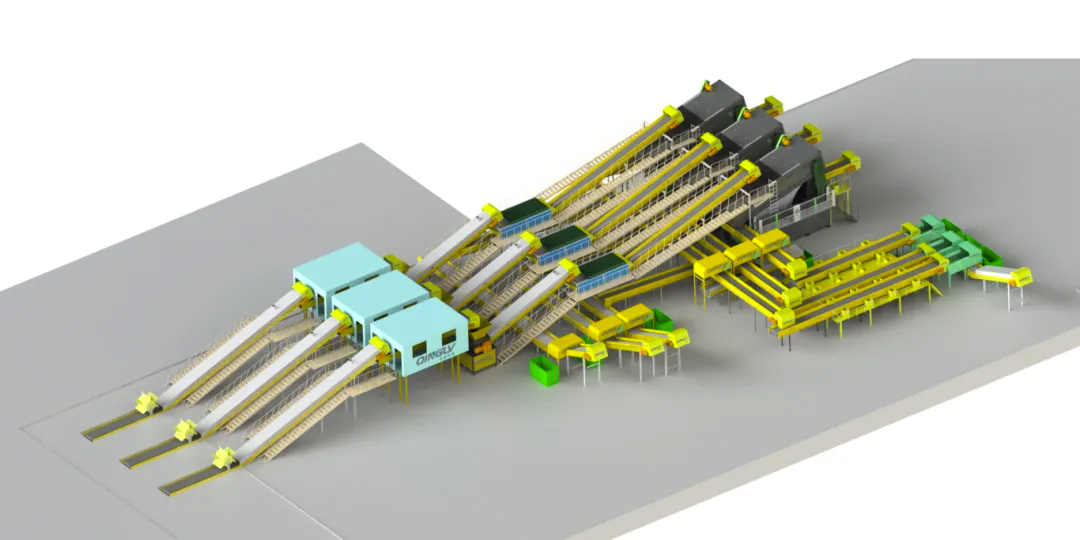

Source:青绿环境

Source:青绿环境

In the context of increasingly stringent environmental policies, the selection of integrated municipal solid waste sorting equipment production lines has become a crucial aspect of urban solid waste management. A set of efficient and stable waste sorting equipment can not only improve the resource recovery rate but also effectively reduce the risk of environmental pollution. So, how can we scientifically choose an integrated municipal solid waste sorting equipment production line that suits our needs? The following analysis is conducted from several key aspects.

First and foremost, clarifying the project requirements and treatment objectives is a fundamental prerequisite. The composition of waste varies from city to city; some are dominated by food waste, while others have a higher proportion of recyclables such as plastics and paper. Therefore, before purchasing equipment, it is essential to conduct thorough research on the local waste composition and combine it with local environmental standards and resource utilization directions to determine the treatment goals. For instance, if the focus is on recycling renewable resources, priority should be given to configuring efficient modules for crushing, screening, air separation, and magnetic separation. If the emphasis is on waste reduction, then functions such as compaction and dewatering, as well as pre-treatment for incineration, should be enhanced.

Secondly, paying attention to the technological advancement and automation level of the equipment is crucial. Modern waste sorting production lines are trending towards intelligent and modular development. It is recommended to choose equipment with features such as PLC control systems, automatic weighing and sorting, and AI-based classification. These features not only enhance the efficiency and accuracy of sorting but also reduce manual intervention and operational costs. Meanwhile, the stability and durability of the equipment are extremely important, especially when dealing with high-moisture and highly corrosive waste, where material quality and sealing performance are key factors.

Thirdly, considering the equipment's production capacity matching and expansion potential is vital. Selecting the appropriate equipment scale based on the average daily waste processing volume is essential to avoid situations where the equipment is either underutilized or overburdened. Additionally, considering the future increase in waste volume due to urban development, reserving expansion interfaces and upgrade space can help extend the equipment's life cycle and improve the return on investment.

Lastly, after-sales service and technical support should not be overlooked. A high-quality supplier should provide comprehensive services such as installation and commissioning, operator training, and regular maintenance, as well as the ability to quickly respond to unexpected equipment failures. Choosing to cooperate with manufacturers that have successful case studies and good reputations can significantly reduce the risks associated with later maintenance and operation.

Selecting an integrated municipal solid waste sorting equipment production line is a systematic project that requires a comprehensive evaluation from multiple perspectives, including technology, economy, and environmental protection. Only by adapting to local conditions and planning scientifically can we truly achieve the goals of waste resource utilization, harmlessness, and reduction, thereby providing strong support for sustainable urban development.

Prev

Prev