Time:2024-11-12

Time:2024-11-12

Source:青绿环境

Source:青绿环境

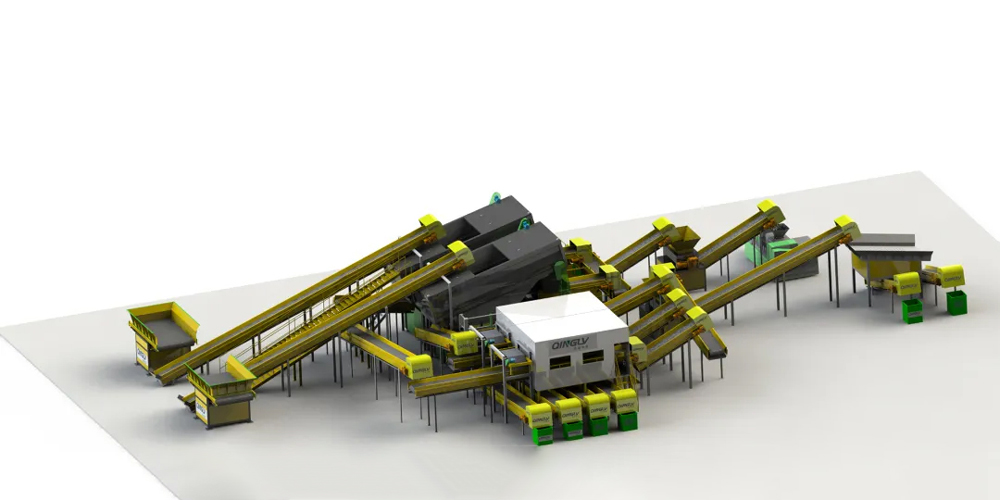

With the acceleration of urbanization, the generation of construction waste is increasing continuously. To achieve the resource utilization of construction waste, construction waste recycling production lines have emerged. These production lines transform construction waste into reusable resources through a series of sophisticated equipment and technologies, thereby realizing the recycling of resources.

The construction waste recycling production line mainly consists of the following parts:

1. Crushing System:

The crushing system is the core part of the production line, responsible for breaking large pieces of construction waste into smaller particles. Common crushing equipment includes jaw crushers, impact crushers, etc. These devices can efficiently crush hard materials such as concrete and bricks into sizes suitable for subsequent processing.

2. Screening System:

The screening system is used to separate the crushed materials according to particle size. Through equipment such as vibrating screens and drum screens, materials of different sizes can be separated for targeted treatment and utilization.

3. Sorting System:

The sorting system uses techniques such as magnetic separation and air separation to separate recyclable materials such as metal, plastic, and wood from the materials. This step is crucial for improving resource recovery rates and product quality.

4. Conveying System:

The conveying system is responsible for orderly conveying materials between various processing stages, ensuring the continuous and stable operation of the production line. Common conveying equipment includes belt conveyors, bucket elevators, etc.

5. Control System:

The control system is the "brain" of the entire production line, responsible for monitoring the operating status of various equipment and making adjustments and optimizations according to actual situations.

Prev

Prev