Time:2024-12-12

Time:2024-12-12

Source:青绿环境

Source:青绿环境

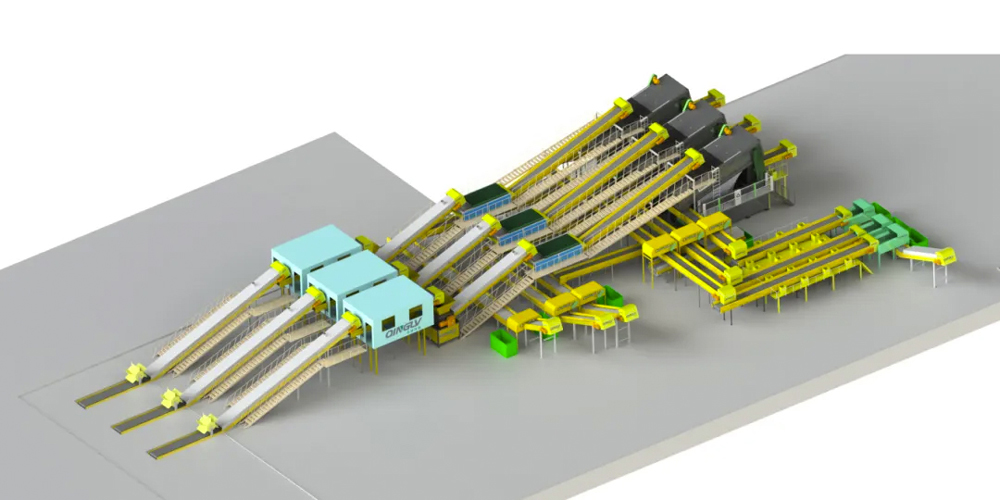

The domestic waste processing production line is a device that classifies, sorts, crushes, and compresses urban domestic waste, ultimately converting it into reusable resources. Its working principle mainly includes the following steps:

1. Waste Disposal and Pre-treatment: Domestic waste is first placed at the beginning of the production line, where it undergoes preliminary screening and sorting to remove large items and hazardous waste. Then, the waste is conveyed into a crusher via a conveyor belt, where it is crushed into smaller pieces to facilitate subsequent processing.

2. Sorting and Separation: The crushed waste pieces enter the sorting system, where various methods such as magnetic separation, air separation, and optical sorting are used to effectively separate different components of waste, such as metal, plastic, paper, and organic matter. This step is the most technologically demanding part of the entire production line and directly affects the effectiveness of waste resource recovery.

3. Compression and Baling: The sorted waste is sent to a compressor, where it is compressed into blocks or strips under high pressure for easy transportation and storage. At the same time, organic waste can also be processed into compost, turning it into organic fertilizer.

4. Waste Gas Treatment and Environmental Protection Measures: During the entire production process, certain waste gases and dust are produced. Therefore, the production line is equipped with specialized waste gas treatment devices, such as dust collectors and desulfurization towers, to ensure that the emitted gases meet environmental protection standards.

5. Data Monitoring and Intelligent Management: Modern domestic waste processing production lines are usually equipped with advanced data monitoring systems that can monitor the operating status of the production line in real-time, including waste processing volume, energy consumption, equipment failures, and other information. Through data analysis, the production process can be optimized to improve processing efficiency.

6. Product Output and Resource Recovery: In the end, the processed waste is transformed into various reusable resources, such as recycled plastic pellets, metal scraps, organic fertilizers, etc. These resources can be re-entered into the production cycle, achieving waste reduction, resource recovery, and harmless waste treatment. In summary, the domestic waste processing production line converts urban domestic waste into valuable resources through a series of complex physical and chemical processes, not only reducing environmental pollution but also providing strong support for sustainable development.

Prev

Prev